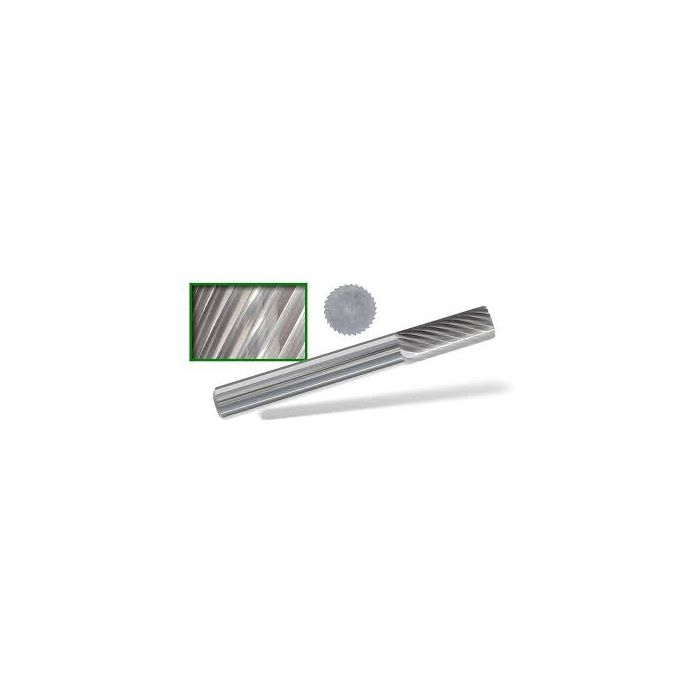

SA-1 cylinder shape burrs are perfect for interior contour work and deburring. As a result of extreme hardness with this tungsten carbide, quite a few on much more demanding jobs than HSS (High-Speed Steel). These carbide burrs are constructed of tungsten carbide burr die grinder bits and definately will learn to soften at higher temperatures, so carbide is usually the best option for long-term performance.

Double cut or Cross cut carbide burrs are generally applied to ferrous and non-ferrous metals, soft steel, and for all non-metal materials such as stone, plastics, wood floor, and ceramic. Double cut burrs will leave a somewhat smoother finish than single cut on account of producing smaller chips since they cut away the material. Use for medium stock removal, deburring, finishing, and cleaning. A double-cut carbide burr is easily the most popular cut and may see you through most applications.

Cut – Double Cut

Max RPM – 70,000, yet it’s uncommon to need more than 35,000 RPM.

Machines Used On:

Die Grinders and hand-held pneumatic grinders

Application:

Ferrous Materials – Cast Iron, Steel, Stainless, Steel, Titanium, Nickel, Wrought Iron

Non-Ferrous Materials – Copper

Other Materials – Fiberglass, Plastic, Hard Rubber, Wood, Stone

Cylinder Shape burrs are good for interior contour work like peripheral and face milling.

Safety Tips & Techniques:

Tool speed will be determined by the material you use your burr on. If you might be experiencing chipping, you’re operating at way too high of speed for your application. Start with a slower speed while increasing as you go along before you get the ideal results

Apply light pressure and allow the tool do the work. Bearing upon the tool will result in reduced tool life and a dull burr.

Always wear proper PPE to add (but not tied to) safety glasses, hearing protection, respirator, and work gloves. Keep all guards set up on your machine.

Avoid use on electrical energy drills; the slower speeds may lead to chipping of the workpiece.

For more information about SA-1 Carbide Burrs check the best resource